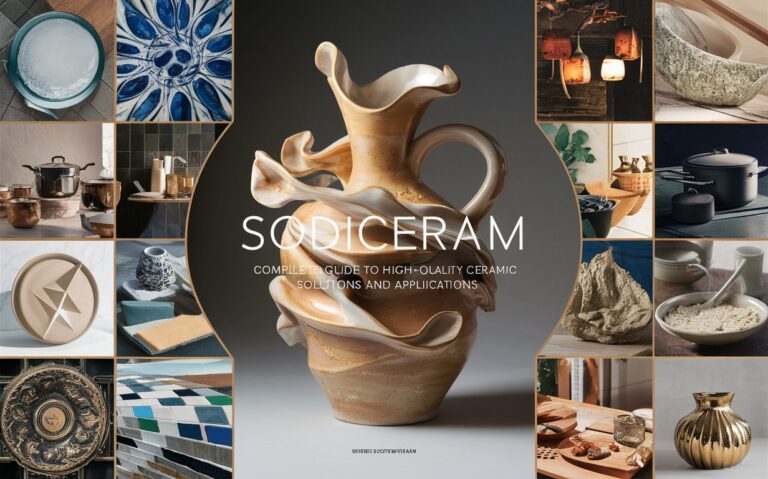

Sodiceram has become an increasingly recognized name within the ceramic and materials industry, representing quality, innovation, and durability in modern ceramic solutions. As demand continues to grow for advanced ceramics in construction, interior design, and industrial applications, sodiceram stands out as a term associated with reliability and technological advancement. Whether used in residential spaces, commercial environments, or industrial settings, sodiceram products are valued for their strength, aesthetic appeal, and long-lasting performance. Understanding what sodiceram represents, how it is used, and why it matters is essential for architects, builders, designers, and consumers seeking premium ceramic materials.

The global ceramic industry is evolving rapidly, driven by sustainability goals, improved manufacturing processes, and rising expectations for quality and design. Sodiceram reflects this evolution by combining traditional ceramic craftsmanship with modern production techniques. This article provides a comprehensive exploration of sodiceram, its applications, advantages, manufacturing standards, and its role in shaping the future of ceramics. By the end, you will have a clear understanding of why sodiceram is gaining attention and how it fits into today’s competitive ceramic market.

What Is Sodiceram?

Sodiceram refers to a category or brand associated with high-quality ceramic materials designed for durability, precision, and visual consistency. These ceramics are commonly produced using refined raw materials, advanced firing technologies, and strict quality control systems to ensure excellent performance across multiple applications. Sodiceram ceramics are typically known for their resistance to wear, moisture, heat, and chemical exposure, making them suitable for both decorative and functional purposes.

Unlike conventional ceramics, sodiceram products often emphasize uniformity and technical performance alongside design. This makes them particularly valuable in environments where reliability is critical, such as commercial buildings, industrial flooring, kitchens, and bathrooms. The term sodiceram has therefore become linked with ceramics that balance aesthetics and engineering, offering solutions that meet modern architectural and industrial standards.

Applications of Sodiceram Ceramics

Sodiceram ceramics are widely used across residential, commercial, and industrial sectors due to their versatility and resilience. In residential construction, sodiceram tiles are commonly applied to floors, walls, kitchens, and bathrooms where moisture resistance and easy maintenance are essential. Their smooth finishes and variety of textures allow homeowners to achieve modern, minimalist, or classic design styles without sacrificing durability.

In commercial environments such as offices, hotels, shopping centers, and public buildings, sodiceram materials are favored for their ability to withstand heavy foot traffic and long-term use. Industrial applications further highlight the technical strength of sodiceram, as these ceramics can be used in factories, laboratories, and production facilities where chemical resistance and thermal stability are required. The adaptability of sodiceram ceramics makes them an ideal choice across a wide range of functional and aesthetic needs.

Benefits of Choosing Sodiceram

One of the primary benefits of sodiceram ceramics is their exceptional durability. These materials are designed to resist cracking, abrasion, and surface damage, even under demanding conditions. This longevity reduces maintenance costs and ensures that installations retain their appearance and performance over time. Sodiceram also offers excellent resistance to moisture and stains, which is especially important in wet or high-humidity environments.

Another major advantage of sodiceram is its aesthetic consistency. Advanced manufacturing processes allow for precise control of color, texture, and finish, ensuring uniform results across large installations. Additionally, sodiceram ceramics are often produced with sustainability in mind, incorporating energy-efficient kilns and responsible sourcing of raw materials. This combination of durability, beauty, and environmental awareness makes sodiceram a preferred option for modern construction projects.

Manufacturing Excellence and Quality Standards

The production of sodiceram ceramics involves advanced technologies that ensure high performance and reliability. Raw materials are carefully selected and processed to eliminate impurities, resulting in a dense and durable ceramic body. Modern firing techniques, often at extremely high temperatures, enhance strength while preserving surface quality. Strict quality control measures are applied at every stage of manufacturing to maintain consistency and minimize defects.

This commitment to manufacturing excellence allows sodiceram products to meet international quality and safety standards. The result is a ceramic solution that performs reliably under real-world conditions, whether in residential homes or industrial facilities. Such attention to detail strengthens the reputation of sodiceram as a trusted name within the ceramic industry.

The Future of Ceramics with Sodiceram

As technology and sustainability continue to shape the construction and design industries, sodiceram is positioned to play a significant role in the future of ceramics. Innovations such as digital printing, eco-friendly materials, and improved recycling methods are increasingly integrated into ceramic production. Sodiceram aligns with these trends by emphasizing efficiency, design flexibility, and environmental responsibility.

The future of ceramics will demand materials that are not only visually appealing but also durable, sustainable, and adaptable. Sodiceram represents this balance, offering solutions that meet both current and emerging needs. As global demand for advanced ceramic materials grows, sodiceram is likely to remain a key contributor to industry progress.

Conclusion

Sodiceram represents a modern approach to ceramic materials, combining durability, design, and advanced manufacturing techniques. Its wide range of applications across residential, commercial, and industrial sectors demonstrates its versatility and reliability. By focusing on quality, consistency, and sustainability, sodiceram continues to stand out in an increasingly competitive ceramic market. For anyone seeking long-lasting ceramic solutions that meet modern standards, sodiceram offers a compelling and future-ready choice.

Frequently Asked Questions (FAQ)

1. What makes sodiceram different from traditional ceramics?

Sodiceram differs from traditional ceramics through its advanced manufacturing processes, higher durability, and improved consistency in design and performance.

2. Is sodiceram suitable for residential use?

Yes, sodiceram is ideal for residential spaces such as kitchens, bathrooms, and living areas due to its moisture resistance, durability, and aesthetic versatility.

3. Can sodiceram be used in industrial environments?

Sodiceram ceramics are well-suited for industrial use because they offer resistance to chemicals, heat, and mechanical wear.

4. Are sodiceram products environmentally friendly?

Many sodiceram products are manufactured using sustainable practices, including energy-efficient production methods and responsible material sourcing.

5. Why is sodiceram popular in modern architecture?

Sodiceram is popular in modern architecture because it combines sleek design options with long-term performance, meeting both aesthetic and functional requirements.